-

About

Us

About

Us Centrifugal

Separation

Centrifugal

Separation About the Inventor

About the Inventor

-

Figures & Test

Results

Figures & Test

Results Environmental

Issues

Environmental

Issues Contact Us

Contact Us

THE PRODUCT

1-

SUMMARY

1-

SUMMARY

Yaz- Dehydrone is a unique invention ,

patented in the U.S. and Canada, has the potential in revolutionizing the two-

phase separation technology. Although it utilizes centrifugal separation , which

is a well known and widely used method , but it is unique in design and method

of operation. It is expected to strongly compete and eventually replace other

types of centrifugal separators presently used in the industry.

2- THE INVENTION

YAZ- DEHYDRONE is a completely new and more efficient method of separation

adaptable to any operation. With no internal or external moving parts, it

requires little or no maintenance and little or no additional energy, if the

fluid is in a flowing state.

A broad patent coverage for the DESIGN and METHOD of

separation has been granted by the U.S. and Canadian Patent offices.

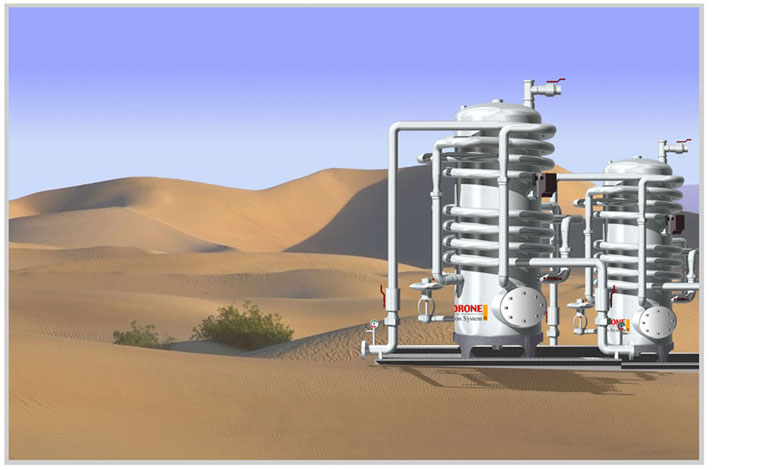

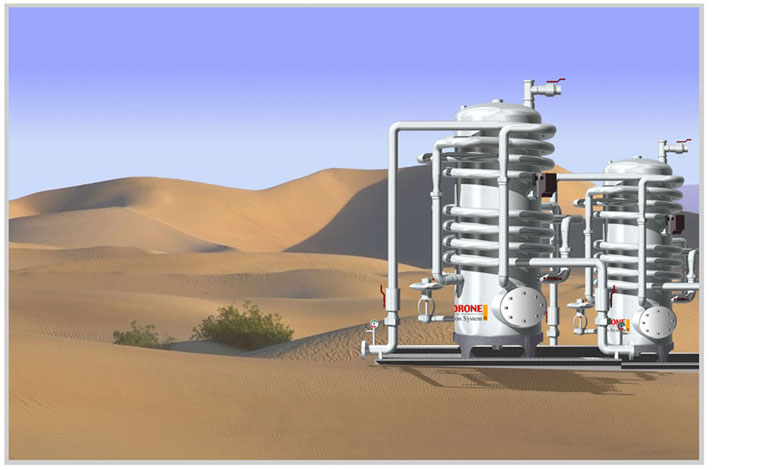

3- THE VESSEL

The Vessel is made from a central cylinder around which a

pipe is wound in a spiral form. From the spiral pipe, at specified turns,

precise openings are made with leading pipes to the central cylinder. These

openings are traps for directing the heavy phase into the central cylinder. The

central cylinder has a level control and a dump valve for discharging the heavy

phase as it reaches a specified level inside the cylinder. A hatch at the lower

end of the central cylinder is installed to remove any solids that may

accumulate with time .Also, this hatch is put to remove solids when separation

of solid/ liquid or solid/ gas is desired.

4- HOW THE SEPARATOR OPERATES

The mixture of two- phase fluid, in this case water in oil,

enters the vessel at the lower end of the spiral pipe and moves upward in a semi

circular motion through the pipe.

For the fluid to flow inside the vessel , if not induced by

the natural flow of the well, a small pump is used for that purpose. An inlet

pressure of 100 psi is normally sufficient.

As the fluid moves through the spiral pipe, the water

droplets ,being the heavier phase, are forced by their motion within the pipe to

the outside portion of the flow. The water droplets are, also, forced together

and coalesce forming a water stream flowing on the outside portion of the flow.

As the whole fluid flows further , the water is caught by the first trap and

directed to the central cylinder, This happens without any turbulence to the

main flow, because the design of the central cylinder is made to operate as a

collection vessel and as a stabilizer to the main flow. In addition , the traps

are also designed that no turbulence occurs when the heavy phase is directed

downward

As the fluid flows further, any water that had not

separated would separate and is caught by further traps alongside the spiral

pipe.

The main separation by centrifugal force occurs in the

spiral pipe and the heavier phase is directed to the central cylinder. Further

separation, however, occurs in the central cylinder for any portion of the light

phase that may have entered with the heavy phase through the traps. This happens

by gravity segregation and the light phase is re-introduced into the main stream

near the exit point.

In principle, Yaz-

Dehydrone is a centrifuge with no moving parts, with no

need for power supply to operate a rotating vessel, with no need of regular

maintenance of the different parts and it is manufactured at a fraction of the

cost. Furthermore , it can deal with mixtures of liquid and gas or solids and

gas which centrifuges cannot do.

Yaz- Dehydrone can separate any two-phase mixtures

,regardless of their concentrations or fluctuation in their concentrations in

the flow.

5- MANUFACTURING COST

A U.S. manufacturer, based in Ohio, has provided an

estimate for manufacturing the first Unit and has estimated 30 to 60 days to

construct the Unit.

The vessel manufacturer has been manufacturing pressure

vessels since1901 and their manufacturing standards meet ASME Boiler and

Pressure Vessel Code and it complies with ANSI. Blue prints, bill of materials

and manufacturing costs are all available and any other manufacturer can build

the vessel based on this information.

Because the vessel is made of only steel pipe and a central

cylinder and few instruments, the cost is extremely low compared with the sale

price that is expected to obtain, considering other separating equipment in the

market, which are sold at prices of $200,000 and $350,000 or more. Yaz-Dehydrone can easily

compete with these prices and have an exceptionally high margin of profit , in

addition to giving superior results.

6- ECONOMIC PROJECTIONS

The initial intended market for the Separator is the

International Petroleum Industry

With the expansion of the global economy, the need for

two-phase separators for new facilities is constantly growing. In addition more

oil wells are being depleted into producing formation water or injection water

with their crudes, which need to be separated. Requirements to replace the

presently inefficient separators or too expensive to operate or maintain, will

also contribute to continuous demand.

The total direct market is projected in excess of $ 3

billion. In addition to the oil industry, other separation processes are largely

hidden from the average consumer. These processes are a part of many industries

from mining to food processing to various manufacturing. The combined U.S.

,Canada and European markets for various separation equipment which are used in

liquid/ liquid, solid/ liquid, solid/ gas and liquid / gas is estimated at over

$ 3.5 billion . Yaz- Dehydrone can easily get a small share of the market in the first three years

which would amount to many million dollars. In a prepared Business Plan The

expectation of sales was estimated at $100 million at the end of 5

years.

Market efforts should focus on replacing two-phase and

three-phase separators used in Oil and Gas operations. Target market should

include offshore production ,where deck space in addition to efficiency is of

primary importance ,in addition to onshore, exploration and

refining.

Yaz-Dehydrone ,

because of its simplicity, efficiency, ease of operation, low manufacturing cost

and little or no maintenance cost should be able to target new customers and to

compete and eventually replace many of the presently used separators because of

their lack of efficiency or to their high initial cost and their high operating

and maintenance costs.

It is envisaged that Yaz-Dehydrone, with aggressive marketing

and further development would suit all different separation needs and would

establish a permanent presence in the separation industry with a large share of

the market.

-

About

Us

About

Us Centrifugal

Separation

Centrifugal

Separation About the Inventor

About the Inventor

-

Figures & Test

Results

Figures & Test

Results Environmental

Issues

Environmental

Issues Contact Us

Contact Us

-

-

Copyright ©2000 Quantum Dynamics Inc. All

rights reserved.

1-

SUMMARY

1-

SUMMARY